In the Linking menu of your CAM settings. Go back and make sure that the box for ‘ Keep Nozzle Down’ is left unchecked

By using the hole command, you can add those features during the hole creation process. If you need to add any other features to the hole, such as a counterbore or countersink, you have to add them as secondary features. I'm not a fan of the sketch a circle and extrude method and here's why.

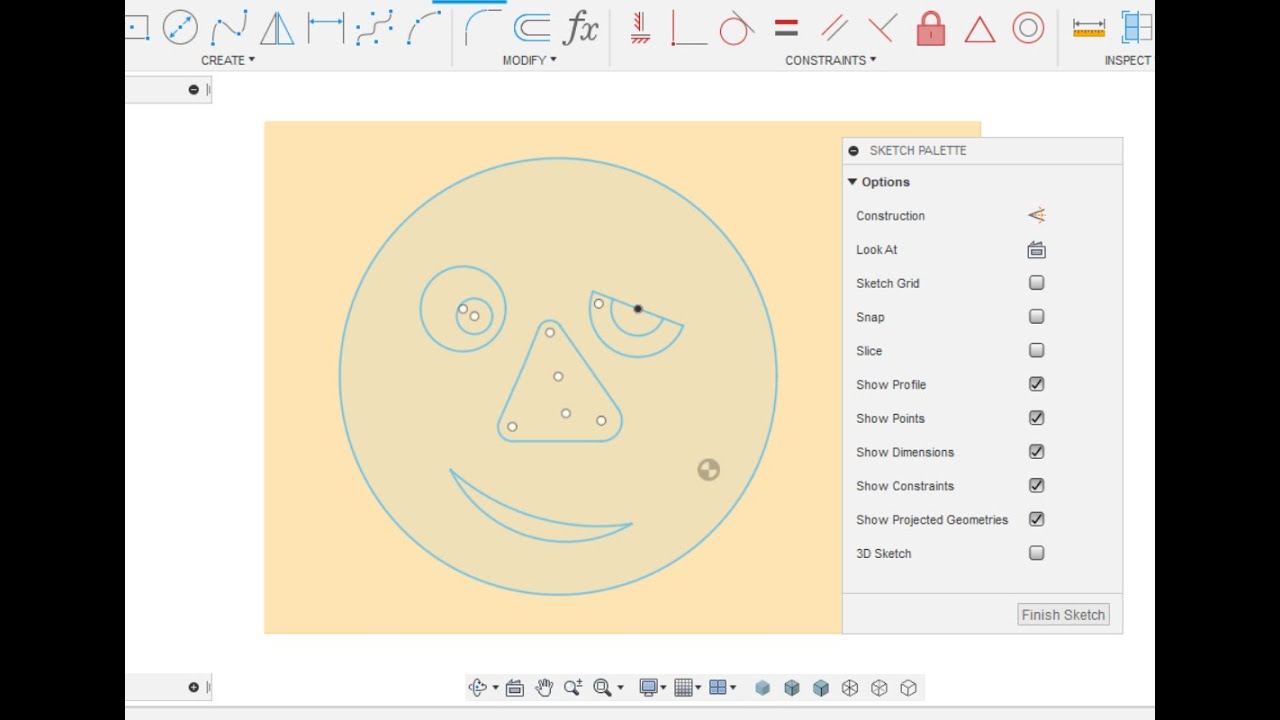

After the points are added to the sketch, you can use the hole command to place a hole at each of those sketch points. You can sketch the holes by drawing a circle and extruding the profile to create a hole, you can place holes directly on the model by using the hole command, or you can also do a hybrid approach by creating a sketch and adding multiple sketch points to that sketch. There are a few different ways that you can add holes in Fusion 360. There are features of the hole command still missing, but fingers crossed that a future update will add those missing options. However, after an update, things work as I thought it they were intended to. In a previous build, some of the functionality to locate a hole using Fusion 360 didn't work the way I was hoping it would. The hole command in Fusion 360 is an area the demonstrates this update cycle. And when a new update is available, Fusion 360 updates itself with no uninstalling or reinstalling required. With Fusion, that cadence has been reduced from about one year to six weeks. The excitement when said feature did make it, and the dread of knowing I would have to wait at least 364 more days to see if that particular feature would make next year's release if it didn't. I remember learning a new version of Inventor was available and hunting down the What's New document to see if that feature I just couldn't live without had been added. One of my favorite "features" of Fusion 360 is the rate at which the product is updated.

0 kommentar(er)

0 kommentar(er)